From time to time, the incessant development of science and technology has forced engineers to solve enormous challenges. With such challenges, the engineering projects in all domains are getting more convoluted and more exhausting. To solve these challenging problems, engineers and experts have always relied on sophisticated tools. Tools like these always assist a company or mechanical design firm in tackling a problem with ease.

One such engineering tool that is widely used nowadays in almost every industry is CFD simulation services. Vital for every enterprise and its engineering projects. Using CFD analysis, experts are able to analyze complex problems involving fluid-solid, fluid-gas, or fluid-fluid interaction.

What Exactly Is CFD?

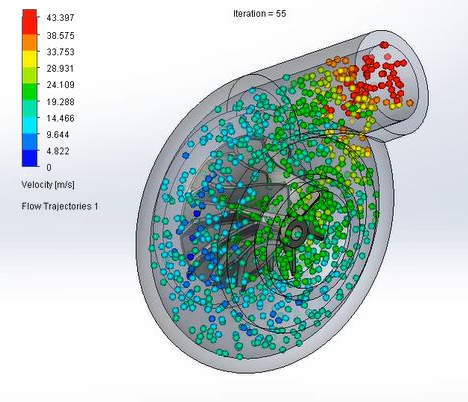

CFD or Computational Fluid Dynamics is a division of fluid mechanics that employs the techniques of numerical analysis and data structure. To find solutions to problems involving fluid flow. Many professionals working in this domain offer CFD analysis services to help engineers solve their problems with fluid flow quickly and precisely.

CFD, as easy it may seem, is actually hard in practice. Based on high-level intricate mathematics and physics. CFD uses Navier-Stokes equations to predict the flow of any liquid or gas. Moreover, these equations help professionals accurately determine the pressure, velocity, density, and temperature of any moving fluid.

Applications of CFD In Engineering Projects

Used in almost every sector, CFD is distinct because of its analytical and simulation capabilities. No matter how complicated the problem is. Intelligently using CFD can help find a favorable solution for it. For this purpose, engineers should always look for CFD consulting and CFD analysis services. To solve their problem quickly, accurately, and cheaply.

Many industries in sectors like – Aeronautics/Aerospace, Automotive, HVAC, Power/Energy, Manufacturing, Product Designing, Oil & Gas, Turbomachinery, etc. Have always relied on CFD analysis to determine answers to their complex and inimitable problems.

Benefits of CFD in Engineering Projects

Innumerable engineering projects in the industry are dependent on CFD Analysis. Mostly because of the myriad of advantages CFD has to offer. To efficiently employ CFD, many companies rely on CFD consulting and CFD analysis services provided by mechanical design firm to solve their problem in a quick and precise manner. Out of all the benefits of CFD services, let’s look at some of the most important ones–

Building More Robust Prototype

Physical testing in engineering problems should never be overlooked. However, in some cases, physical experimentation can be difficult to achieve, and in other cases, it can be really expensive and time-consuming.

CFD does not remove the need for physical testing, nor should it. Instead, CFD changes the nature of testing and experimentation. With the ability to accurately simulate any model, engineers can modify and improve existing designs.

Moreover, rather than wasting time on simple validations and verifications. CFD allows design experts to explore other unseen areas of the problem through parametric studies in CFD. This, in turn, helps them judiciously build and design more robust prototypes. Seeking any reputed mechanical design firm dealing with industrial design prototyping will help in effectively building desired prototypes using CFD and other CAD software.

Well Informed Teams

Valuable insights dealing with manufacturability and performance can be generated using CFD analysis. In the designing process, CFD delivers flow field data at high resolution both in time and space. Thus, helping designers and other team members to comprehensively understand their model and the scope of improvement.

In projects where physical testing might not be feasible. CFD simulations can help different teams understand the model in its actual environment. With advanced graphics, CFD programs accurately show complicated fluid flow and thermal gradient visuals. In a way that is considerably much easier to comprehend.

Furthermore, seeking the help of a mechanical design firm offering CFD consulting and CFD analysis services can help achieve desired results quickly. Besides, with their industrial design prototyping services, these experts can implement their acumen to attain profitable outcomes in no time. Most importantly, these professionals work hand in hand with your team to discuss the possibilities and scope of your engineering project at every step.

Is Using CFD on Engineering Projects Expensive?

With the ample benefits of CFD analysis, many people might fall into thinking that using CFD for their project would be exorbitant. In reality, employing CFD, you can expect savings in both time and money in the design of products impacted by flow-related phenomena.

Any reputed mechanical design firm that offers industrial design prototyping, CFD consulting, and CFD analysis services. Can not only solve your CFD problems but can also help in modifying existing designs to increase profitability.

Is There Any Alternative To CFD Analysis?

With rising complexities of engineering problems dealing with fluid flow. In reality, there is no actual alternative to solving problems with Computational Fluid Dynamics. Decades ago, engineers mainly relied on hand calculations and practical experimentation to find solutions for their fluid-flow problems. However, today there is no limitation to the difficulty of any engineering project. Thus, in the 21st-century, the reliance of entrepreneurs, companies, and experts on CFD consulting and CFD analysis services is inevitable and irreplaceable.