CFD engineering can quickly resolve product design paradoxes. A CFD consultant can help product design optimization by all but eliminating design failures. CFD companies help product teams successfully meet product launch deadlines. CFD enables the analysis of complex problems involving fluid-fluid, fluid-solid, or fluid-gas interaction.

By simulating the action of thermo-fluids in a system, the performance of designs can be analyzed, optimized, and verified. This can all be done before the creation of costly prototypes and physical tests being undertaken.

Functions of CFD analysis

So what is the main function of CFD? The basic and key function of CFD analysis is to predict the outcome of fluid dynamics. For doing that CFD uses conservation laws, mainly referring to the conservation of mass, conservation of momentum, and conservation of energy. Some basic physics laws. CFD analysis takes these laws and some numerical data to use in the Navier Stokes equation and a data structure profile. CFD analysis services require the help of a digital computer to analyze fluid data and predict a quantitative outcome of those fluids in a system.

With these simple numerical and data analyses, CFD can perform Heat transfer analysis, thermal analysis service, and also flow analysis services.

With these vast services of CFD, it is used by Nasa in aerospace engineering. Big car companies use it for analyzing their new car model and its performance in a simulated virtual real world.

The conservation of energy and matter of CFD analysis also helps pharmaceutical companies to predict the outcome of various chemical reactions.

Now that we know about the basic functions of CFD, let’s look at their benefits using some real-world examples.

Designing a better model without huge investments

Engineers and mechanics are continuously working on designing better engines and pieces of machinery. But no design can be completely approved for mass production without real-world test results. The modern engines and machines designed by engineers are often so complex that it will take a significant amount of money to make one prototype. And if the test fails, the investment will be a total loss.

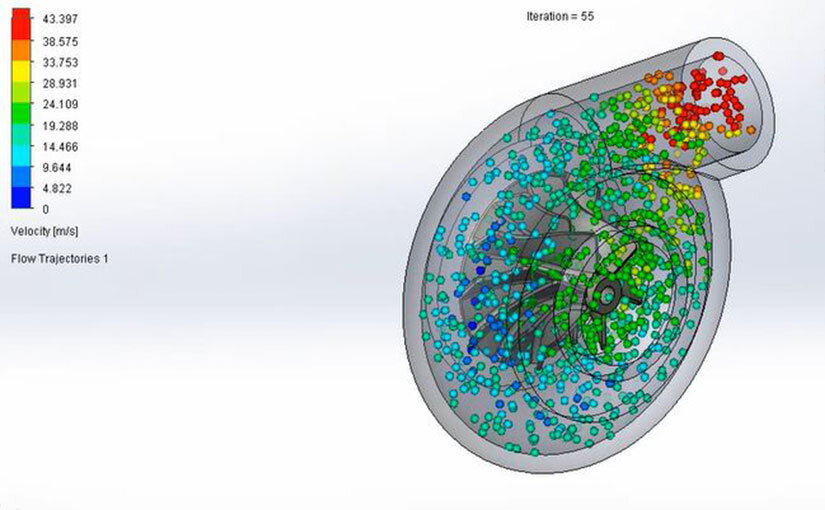

That is where CFD comes in. CFD can simulate a real-world environment to test a virtual model of that engine. With a flow analysis service, CFD can easily predict the movement of fuel, air, and vapor in the engine. And with thermal analysis service, you can perform heat transfer analysis on the engine body and identify potential errors and opportunities to fix your model and rebuild a new one to analyze it again and repeat the circle to create a perfect engine for mass manufacturing. This saves the researchers from taking the risk of making huge investments.

Car and plane designers and manufacturers use this method for developing new efficient engines.

Experimenting on a model unlimited time

Before the invention of CFD, engineers could not always go far with their products because they hardly had enough prototypes to run tests on. As a result, products in the past were often underdeveloped and easily breakdown in extreme environments. But now they don’t have to worry about prototypes anymore because they can do unlimited tests of different environments on their models without any real cost and investments.

Designing a proper ventilation system before implementation

Admit it or not, ventilation systems are one of the most important parts of any modern design. Whether it’s a building, plane, or car. If it has a ventilation error, it can pose a life threat to its passengers.

Flow analysis service and thermal analysis service can predict the flow of air in a structure within its environment both stable and moving.

This section of CFD analysis is known as HVAC, short for heating, ventilating, and air conditioning.

Architects use it to develop a better efficient air distribution system in their buildings. Engineers use it to develop a stable airflow for the passengers inside a plane or spacecraft. Air Conditioning engineers use heat transfer analysis to analyze the effectiveness of their new designs.

Testing new drugs without real test subjects

CFD uses conservation of mass and energy, two basic rules in both physics and chemistry. Because of that, many chemists also use CFD to try out new drug formulas. Drugs are chemicals. They work by reacting with the chemicals present in our body. chemical reaction. CFD can reliably predict the outcome of chemical reactions if you give it the correct data and guidelines.

The benefits pharmacists are getting is that they don’t have to test the drug on alive animals and gamble on their life for the new formula’s success.

No risk weapons design

Weapon design is a critical sector of science. Scientists and engineers have to be very precise and decisive with their formula and design of new weapons. Weapons designing requires expertise in two science sectors. Physics for aerodynamics of the missiles and chemistry for the internal chemical reaction for the explosion, boom, etc.

One small mistake in the test field can cause huge life loss. But these weapons can be easily tested in a CFD analysis. The best benefit engineers will get here is that they don’t have to risk their lives to test a new weapon.

Conclusion

So, these were some of the benefits of the CFD analysis service. The virtual engines of the CFD service are getting stronger day by day, pushing its possibilities further.