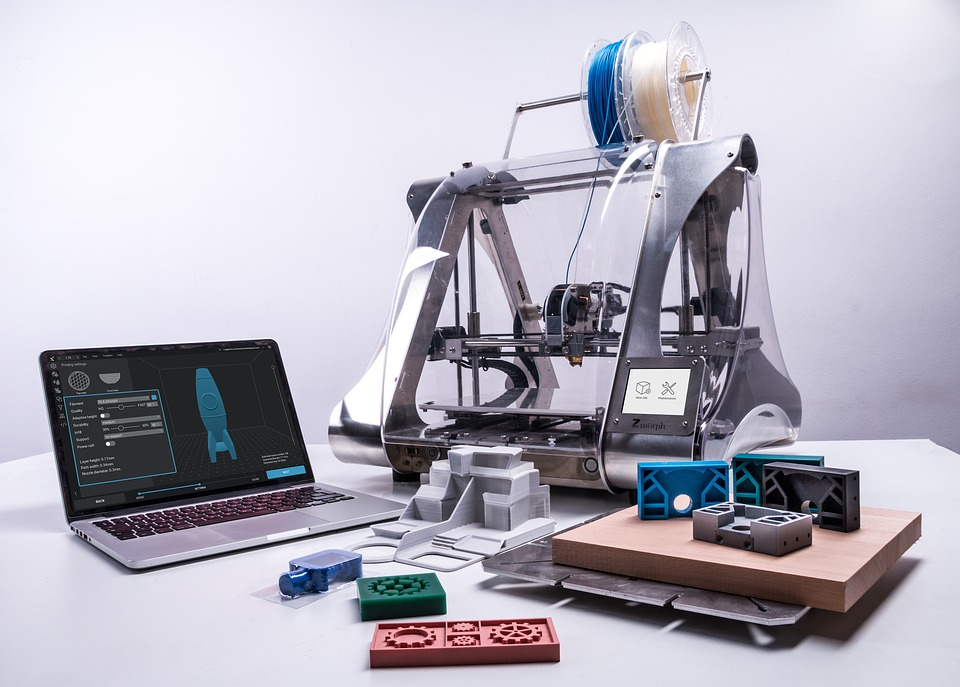

Considering a better approach for your prototype manufacturing needs? Look no further than 3D Printing.

Why?

It’s one of the most advanced additive technologies in the market that offers high levels of accuracy when crafting your product prototype to perfection.

Compared to old-school concept prototyping and manufacturing techniques, 3D Printing uses a layer-by-layer approach. This lets you build objects one layer at a time and leaves room for plenty of customizations.

However, considering other product prototyping methods and their pros and cons, the question remains: “Should you really use 3D Printing for prototype development?”

To make it simple, we’ve compiled promising reasons why we think 3D Printing is a great choice for consumer product prototyping and why you should use it for your product creation.

Here they are:

Faster Than Other Methods

What distinguishes 3D Printing from the rest is its ability to rapidly produce prototypes from scratch. This is what has given 3D Printing a familiarity with the term ‘Rapid Prototyping.’

Unlike the past where you had to wait for days or even weeks to get your prototype ready, 3D Printing easily lets you create your prototype in little more than a few hours.

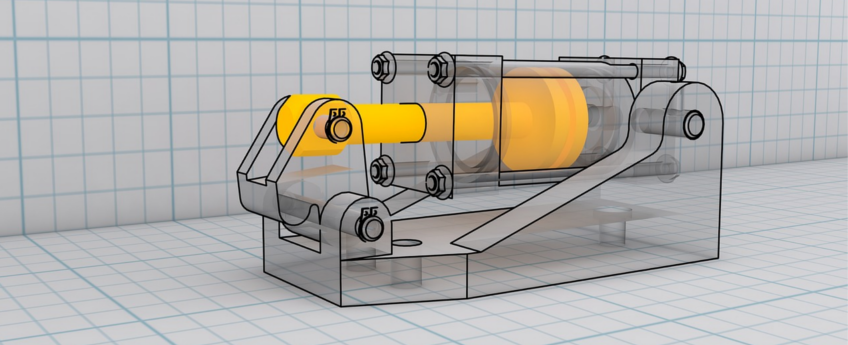

All you have to do is create your design as a CAD model, upload it to the 3D Printer, and see your idea come to life in the form of a prototype. This is great if you want to produce functional end parts in low, high, or custom volumes and save time.

3D Printing can thus help you manufacture and test custom parts in less time as well as modify it without disrupting the speed of your manufacturing procedure.

Is speed your #1 priority? Then 3D printing is the way to go.

Saves More Costs

Cost is a major concern among businesses and this is where 3D Printing shines when it comes to prototype development. 3D Printing helps reduce the costs in almost every term be it machine operations, transportation, or material costs.

As 3D Printing requires minimal overlooking for machine operations compared to more traditional machines, the cost of labor is significantly reduced.

What’s more, 3D Printers use less power than traditional heavy machinery which also helps cut down costs.

In terms of travel costs, 3D Printing makes it easier to produce prototypes from start to finish entirely in one location thus not having them to be moved from one location to another. This helps save shipping costs to a great extent.

More Material Choices to Choose From

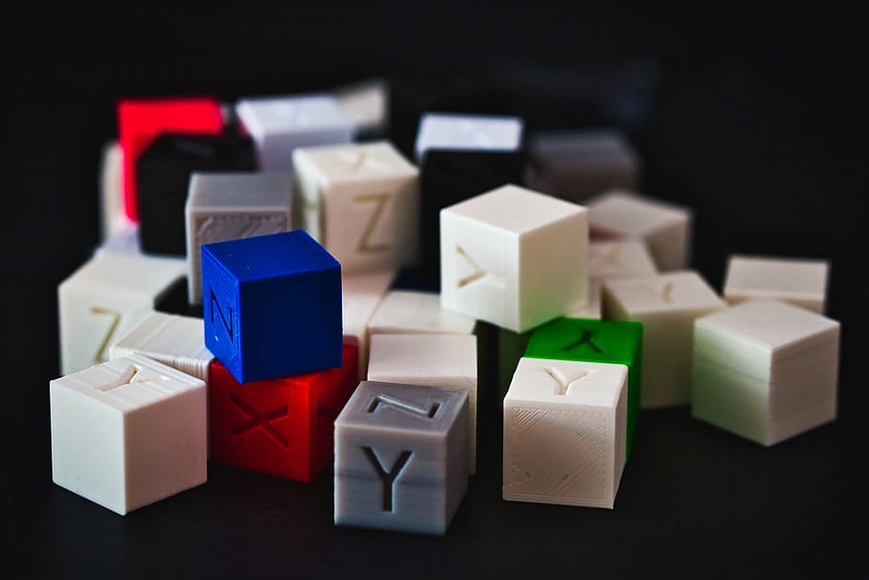

Thanks to the popularity and rapid adoption of 3D Printing for prototyping, the availability of different filament options has increased over the years.

Today you can choose anything from materials like PETG thermoplastics to ABS, Wood, Sandstone, and even Amphora.

With such a wide range of options, businesses can experiment with different types of materials ideally suitable to make their prototype. This gives them more freedom and customizability to create their prototypes.

Great for A/B Testing

The whole idea behind creating prototypes is to test multiple concepts and finalize the one that meets your expectations.

Doing this with traditional prototyping techniques takes significantly more time. From creating the prototype to refining it, traditional methods can take a considerably longer time to A/B test your prototypes.

In comparison, 3D Printing lets you rapidly test different prototypes in a short span of time. By simply altering your changes in the CAD file, you can create different variants of your original product prototype in quick successions.

Less Wastage of Materials

Sustainability is another reason what makes 3D Printing a good choice for prototyping.

Using subtractive techniques results in plenty of wastage of raw materials. This happens as prototypes have to be carved out from a single block of material.

3D Printing, being an additive technique, utilizes only a specified material quantity required to create the prototype. This ends in less wastage of materials.

Also, 3D Printing materials are quite recyclable and leave less impact on nature.

Risk Mitigation During Manufacturing

With the help of 3D Printing, businesses can verify product prototypes consistently well before the manufacturing stage. This helps eliminate risks early on and prevent disastrous outcomes.

Thus, 3D Printed prototypes can make businesses aware of potential flaws their designs might have before they even make it a reality.

This helps them save both costs and time.

Gives You a Competitive Advantage

3D Printed prototypes are ideal if you just want to create 3D real-world mockups of your product idea and present them to potential clients.

Thanks to the speed and efficiency of 3D Printing, businesses can shorten the prototyping lifecycle and deliver quality prototypes to clients in less time.

As clients get a real-world representation of your product they get a much better idea of what you have to offer. In this manner, 3D Printed prototypes eliminate the risk of communication or information loss.

Apart from that, these models can be used as excellent market testing tools to gain feedback from customers and investors, thus giving you a competitive advantage in the market.

Final Thoughts

Well, as you might have guessed by now, 3D Printing is arguably the most popular and cost-effective prototyping approach of all.

Offering plenty of benefits in terms of cost, speed, and reliability, it’s a great technique you can use to make your product a reality.

With that being said, are you looking for a cost-effective prototyping solution for your product? If so, we have a whole range of 3D Printing Services to help you out.