Years after years, effectual tools and methods have been employed incessantly to conquer design challenges in the engineering arena. The industrial revolution has brought many techniques for designers and experts to enhance existing designs to create a quintessential product. Scale model prototyping is no different. Scale modelling has empowered entrepreneurs, businesses, and industries to study their product’s design at a rapid pace. Using scale models identifying design faults has become easy, and improving existing designs has become even easier.

Years after years, effectual tools and methods have been employed incessantly to conquer design challenges in the engineering arena. The industrial revolution has brought many techniques for designers and experts to enhance existing designs to create a quintessential product. Scale model prototyping is no different. Scale modelling has empowered entrepreneurs, businesses, and industries to study their product’s design at a rapid pace. Using scale models identifying design faults has become easy, and improving existing designs has become even easier.

Apart from being a quick method, Scale mode prototyping is also a cost-effective means for professionals to efficiently scrutinize their product’s design.

Here is how to scale model prototyping addresses design gaps,

A Prolific Marketing Tool

For businesses selling products that are complicated in geometry and size. Scale modelling offers an effective way out. For instance, for architectural companies, there is no better way to market their project than a fully detailed scaled model. Scale models offer such industries the ability to create and depict the project in an engaging and informative way. Not to forget, exquisitely instructive models are known to create a strong impact on customers.

Thus, in such businesses creating a tangible model that beholds the quality of the actual product ensures an edge over competitors.

Improve Existing Designs

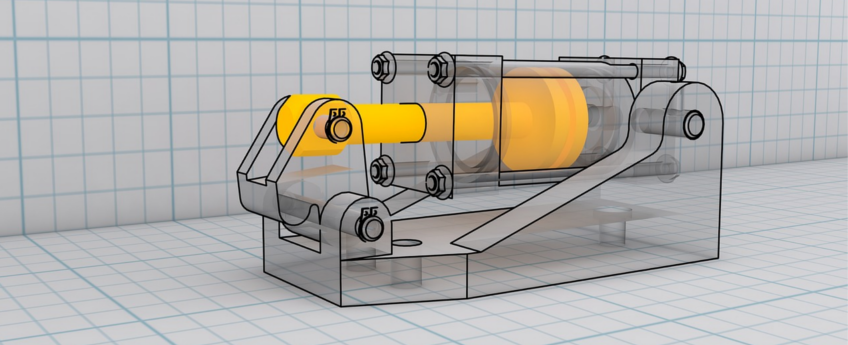

Scale models are a way to represent intricate models into something that is easy to comprehend and that too cost-effectively. Individuals and enterprises using scale model prototyping can discern the product’s design elements to identify faults and loopholes to advance in the product development cycle. Notably, with scale model prototyping, designs are not limited to lines and boxes. Product design firms offering innovative new-age scale modelling services can effortlessly produce scale models with intricate curves and shapes.

Moreover, rather than studying a design on blueprints and paper. Analyzing an actual scaled model gives detailed information on the product’s aesthetics, structural, and physical aspects

Transform Intricate Designs in Simple Models

When dealing with clients for whom blueprints are bewildering. Scale model prototyping offers a way to showcase the product in a scale model that accurately depicts the design intricacies and physical aspects. Scale models offer a relatively straightforward means for businesses and professionals to please clients with their design. Therefore, scale model prototyping serves as a communication tool for explaining blueprints to visually appealing 3D scale models.

With a plethora of other advantages of using scale models besides the one listed above, The real question boils down to how easy it is to build a custom scale model?

Building Custom Scale Models

From the Architectural Industry to the Mechanical industry, From Engineers to Marketers, custom-designed scale models offer a productive solution to many encountered design challenges. Specifically, built custom 3D scale models help too –

- Accurately Study Design Elements

- Display the proposed design in Exhibits

- Market the product effectively

- Perform in-depth physical scrutiny

- Gain valuable Feedbacks from potential clients

Scale models can satiate the requirements of different people and industries with varied demands, from folks looking for affordable prototypes to businesses looking for functional scale models. An established new product consulting firm offering comprehensive scale modelling services can assist both. Moreover, custom scale models give professionals the ability to get a physical feel and view of the design. They can even decide if the existing design works or if any minor design tweaks are required before starting with the actual production.

Scale Model Prototyping is a tool, to say the least, that helps tackle any design conundrum. For instance, a real estate company building a real estate project can build 3D scale models of buildings, houses, etc. Thus, helping to lay the foundation of the actual project by deciding on the most convenient and effective placements of the infrastructure.

On top of that, scale models serve as larger (or smaller) replicas of pre-existing products or objects. For example, when designing an intricate part that has to be used in a machine assembly, developing scale models for the other parts and components of the same assembly can help get an overview of the physical and functional requirements for the part to be designed. This helps experts and engineers accurately contrive the physical requirement of the product without jeopardizing other crucial parts’ safety.

Even better, replicas of one object can be created in large quantities using scale modelling. For instance, multiple 3-D models can be displayed at different locations and venues when exhibiting a product. Generally speaking, the usefulness, practicality, and functional ability of custom scale models depend largely on the requirements of the individual or business.

In a Nutshell,

Scale model Prototyping offers a productive solution to address design gaps in existing product designs. Seeking the assistance of engineering design firms developing an accurate scale model within the budget will be possible through their stellar scale modelling services.

With scale modelling, no project is too small or too large, from micromachine parts to hefty cityscapes-anything can be transformed into physical 3D scale models. Besides the size, no matter how complex the design, seeking the help of product design firms can Fast Track the process of prototyping by accurately developing scale models. To, say in simple words, for the best experts, if there’s a design, there’s a physical model for it.