Let’s be honest, product development prototyping is a complex process that requires great attention to details and technological expertise. Whether you’re a newcomer to the product designing industry or a veteran, there are a few rules you need to abide by to have a successful product prototyping career.

To make matters even more complicated, There are a few common mistakes that can hamper the prototyping and model making for product design even further. Even the smaller mistakes at any stage of product designing and prototyping may cost a lot for a company.

Fortunately, these mistakes can be easily avoided with proper initial planning and thinking outside the box. All you need is technical know-how and eye for the details and you can save your company a fortune by avoiding these common errors in product prototyping.

Want to know how to take care of these roadblocks to efficient manufacturing? This blog will tell you just that. Let’s take a look at 6 avoidable mistakes in prototyping and how to avoid them.

Without further ado, let’s get right into it.

1: Rushing Towards Prototyping Phase

One of the most common product design prototyping mistakes committed especially by newcomers is the urge to get into the product prototyping phase as soon as possible.

A professional prototyping service provider should know that product design undergoes numerous stages like idea generation, feasibility analysis, initial concept arts, rapid prototyping, and final product manufacturing.

Each one of these steps is crucial for the success of your product idea. If your initial planning is not up to the mark, it’ll affect your entire product designing process including prototyping.

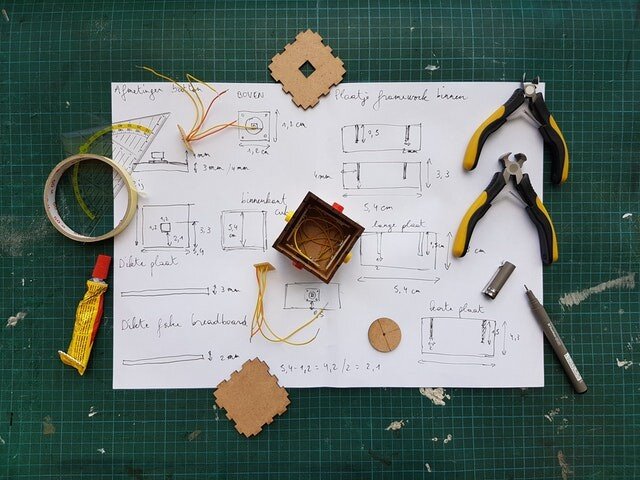

Take your time in understanding your product idea and ways to bring it into reality. Pay close attention to your product’s shape, size, and dimensions, and functionality early on to smooth out your prototyping phase.

If you’re doing it for your clients, listen to their requirements and product goals, analyze the feasibility of the product, create a concept art and beta design of the product, and refine the prototype to perfection. Jumping straight to the prototyping phase without initial research will affect your product design in the long run.

2: Getting too Attached to Your Initial Idea

It’s rather easy to get too attached to your initial product idea. After all, it’s the perfect vision of your product that can make everyone’s life better. However, as the mad titan once said, “the reality is often disappointing.”

Almost 90% of all initial ideas have to undergo a drastic change before making it available to end customers. Whether it’s due to the product’s design, functionality, ergonomics, cost-effectiveness, and ever-changing customer preferences.

It is important to remember that your initial product idea is a pathway for a successful product, not a destination. The entire point of rapid prototyping is to make frequent changes in your product design to become commercially viable and functional.

3: Spending way too Much Time on the Visual Details

Visual accuracy is an important aspect of prototyping. Prototypes work as a visual representation for your clients and stakeholders. Also, it can be used for refining the product design to perfection.

However, spending too much time on making your prototype the exact visual replica of the final product can waste some precious time in product designing.

Confused? Let us explain even further.

Firstly, prototypes are meant to be disposable. They aren’t the final product that can be sold into the market, just a visual replica of the one. You can save some time by creating a decent prototype and focus more on refining your final product to perfection.

Secondly, it’s not worth spending too much time on the prototyping phase once you’re satisfied with the results. Other than a few tweaks now and then, the final prototype should be kept as it is and be used as a referral point only.

4: Choosing the Wrong Tools and Process

You’ve avoided all the mistakes mentioned above and finally got to the prototyping stage of product development. Now, it is important to choose the right prototyping tools, process, and approach for a variety of product types.

Remember, every prototyping equipment is designed differently. They use different materials, has different input methods, and provides prototypes with varying degree of perfection and surface finish.

For instance, ABS 3D printers are mostly used by hobbyists with poor details but the equipment is affordable, making it ideal for making toys and artifacts.

PLA provides a better surface finish which is essential for 3D printing consumer products.

Veroblack/Verowhite is used in product design industries for creating a near-perfect replica of the product with excellent surface finish and great attention to the details.

A professional 3D printing service provider should understand the difference between each of this equipment and which one is most suitable for certain products.

product development prototyping companies have a distinct advantage of having a variety of prototyping equipment and experts to operate them and provide cost-effective solutions to the clients.

5: Designing Prototypes Without Testing

Like an actual product, the prototype also needs to undergo numerous testing to maintain the proper functionality. Rapid prototyping has allowed us to create prototypes in rapid succession which saves a lot of time during a crucial product designing stage.

However, if you keep on designing replicas of the product without prior testing, you are practically wasting your time and prototyping supplies. Whether it’s through physical examination or virtual simulations, you must test your prototypes in detail before moving towards the next step.

6: Delays in Prototyping

Finally, the biggest mistake during the prototyping stage is delaying the entire prototyping procedure. As I’ve mentioned before, the biggest reason for this is focusing too much on visual details. Some other reasons for the delay in prototyping include equipment malfunction, lack of efficiency by operators, and hiring third-party prototyping services with little experience in the industry.

Delaying the prototyping process beyond a planned period can have a serious impact on your product’s success. Technology is changing in such break-neck speed that old products are getting obsolete every month.

Any unplanned delays in prototyping can make your product obsolete, competitors can bring a similar product to you and claim the patent, or your entire product needs to undergo drastic changes during the manufacturing stage which incurs additional cost to your company.

You can avoid this by following all the points mentioned above, or by hiring your local product development prototyping agency with hands-on expertise and experience.

Final Thought

These are the 6 most common roadblocks to effecting product prototyping. The most common mistakes made during product prototyping and ways to avoid them to release your product before your competitors.

Looking for your local consumer product prototyping in Houston, Texas? Well, look no further as we are among the leading industrial product designing company with well-equipped prototyping and CNC workshop and provide timely results.

Just send us your prototyping requirement and get the best prototyping solutions in no time.